In an industry such as packaging, both accuracy and speed are vital components that determine the quality of the end product. A slitting machine helps to enhance the quality of packaging materials by dividing a roll of packaging material into desired lengths with exact precision.The usage of these machines aids in maintaining product quality, minimizing material costs, and enhancing productivity. Selecting a professional slitter rewinder machine manufacturer can have a positive effect on the efficiency and quality of your packaging operations. In this piece, we will talk about the slitting machines which give better quality of packaging materials and the things companies need to keep in mind when purchasing such equipment.

Table of Contents

The Importance of Slitting Machines in The Process of Packing Production

Slitting machines are indispensable in the process of turning basic materials into a finished item of packaging. The machines slice wide rolls of plastic films, aluminum foils, paper, and laminates to narrower strips, achieving the desired level of accuracy and precision required for packaging. These pieces must be cut with great accuracy through slitting machines to ensure the packaging material looks and functions as intended. Machines are therefore an indispensable part of the production cycle.

The edges on every piece of a well operated slitting machine are smooth with no visible defects or cuts, nor is the material deformed, all of which could ruin the overall quality of the packaging. Food and drink services, pharmaceutical companies, and those in e-commerce make use of slitting machines with great care as they aid greatly in protecting the integrity of the packaging and the quality of the goods within. Modern automated slitting machines help reduce downtimes improving workflow as they are capable of high speed production. Also, slitting machines that have tension control systems facilitate better distortion free handling of materials enabling high-quality output. In flexible packaging, slitting and sealing together with other branding strategies are done precisely. This makes accurate cutting necessary.

How Material Quality is Enhanced by Slitting Machines

The best enhancement you gain from slitting machines is the quality of materials, which is their primary advantage. With straying edges, poor positioning, and thickness inconsistencies that affect the overall outer structure of the final package, these machines take precise measurements in place to ensure accurate cuts. This leads to more accurately packaged materials, making them durable to the external conditions as well.

Slitting machines also improve efficiency and protect the environment by reducing waste materials from the rolls. Programmable features and variable cutting widths allow manufacturers to save materials, resulting in lower costs and more eco-friendly production methods. Moreover, advanced slitting machines have quality features such as a tension control system that facilitates smooth cutting without causing distortion or tearing of the material. This is critical for industries where the smallest imperfections can cause pack failure. The ability to maintain constant and uniform material thickness ensures even product stability and greatly improves the efficiency of the packaging process. Companies gain the ability to produce packaging materials with excellent surface finish and precise dimensions which lowers rejection rates greatly improving brand image with the adoption of advanced slitting machines.

The Importance of Choosing the Right Slitter Rewinder Machine Manufacturer

Selecting the right slitter rewinder machine manufacturer can significantly improve the packaging quality and production efficiency of a business. This makes it imperative for every business to select a reliable manufacturer of slitter machines. High-end manufacturers guarantee the performance, accuracy, and usability of their machines, and therefore stand behind their products. With a machine from a reliable manufacturer, maintenance costs and downtime is minimized along with ensuring constant quality in packaged goods.

High-quality companies equally provide tailored solutions for distinct business applications. Whether a company needs high-speed slitting of flexible packaging film or specialty materials precision cutting, partnering with a knowledgeable manufacturer guarantees advanced features and technical assistance. Furthermore, top companies enhance their machines efficiency by integrating automation and digital control systems, which reduces slitting errors caused by human operators.

When selecting a slitter rewinder machine manufacturer companies must evaluate the customer service offered, spare parts provision, and warranty period. Containers that actively offer technical support and training programs make it easier for clients to adapt the machines into the production lines. Partnering with reliable manufacturers ensures integrative, durable, high-quality machines designed to withstand rigorous modern packaging operations. The right manufacturer will also provide constant slitting innovation, and newest technologies so businesses remain relevant in changing markets.

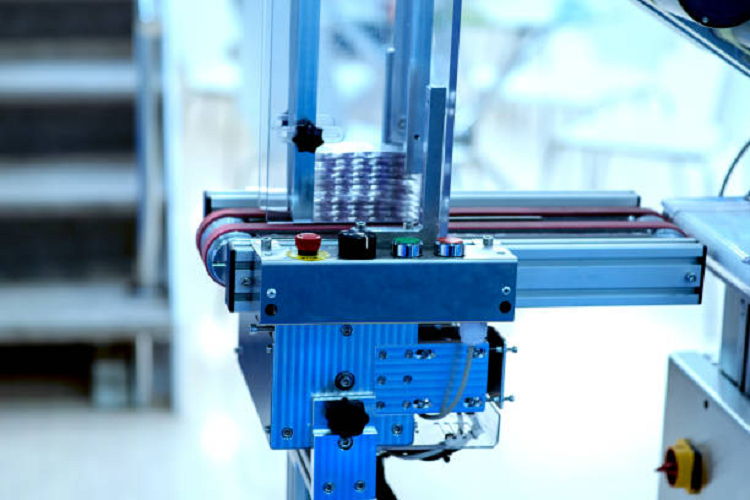

Important Elements of a Slitting Machine

A slitting machine is important in any business, so when choosing one, it is good to keep in mind several features that cut across performance and material quality. Acceptance tolerances is one of the most crucial, as it influences the cut quality and the degree of uniformity of the end product. The utmost achievable quality is provided by machines with servo motors and laser cutting where accuracy is guaranteed.

For higher scale production, speed and automation performance is vital. The most advanced slitting devices have inline programmable logic controls, touch screen consoles, and automatic angle adjustment blades, and therefore can be operated unattended with higher efficiency. Compatibility with different materials is another consideration. Some devices only work with paper and films whereas some other machinery works with metal foils, textiles, or composite materials.

Moreover, systems that control tension and align the web are critical for maintaining cutting accuracy while avoiding distortion of the material. These features assist in ensuring stable slitting, minimizing errors with consequent improvements to the packaging quality. Efficiency in operation over the long-term is also aided by investing in machines with advanced safety features, easy maintenance access, and energy-efficient parts. A slitting machine with the capability of adjusting to a wide variety of materials with minimum wastage is undoubtedly an asset in any packaging production area. Companies aiming for expansion in the future should consider purchasing slitting machines designed with modular expansion functionalities to easily upgrade equipment as production needs grow.

Conclusion

Packaging machines which need support on-web tension control, material slitting, and packaging require slitting machines which guarantee control over precision, minimize waste, and optimize operational efficiency. The right designed slitting machines are durable and aid in sourcing for quality materials in industry. In choosing a slitting machine, businesses have to ensure that there is an emphasis on cutting accuracy, speed, material compatibility, and automation features because they greatly determine the return on investment.

Upgrading to an enhanced slitting machine can help a business improve its production processes, packaging standards, and save money over time. A good manufacturer with the right equipment guarantees dependable results, which assists a packaging company to stay ahead in the changing world. As the industry requirements change, companies that employ modern slitting technology will be in a greater position to provide fresh ideas, increase productivity, and fulfill the constantly rising expectations of many nations’ industries.