As the world of manufacturing moves quickly, rapid machining stands out as a way to get things done quickly and efficiently. This new way of doing things makes ideas into real products much more quickly than ever before.

But what does rapid machining mean, and how does it help businesses? It opens up a world of possibilities when you look into its different techniques and processes. Rapid machining can be used for everything from making prototypes to making the whole thing.

Come with us as we look into this technology in more depth. Find out how rapid manufacturing services are changing the way things are made in the future.

Table of Contents

CNC Machining

CNC (Computer Numerical Control) machining is a super cool way to make things quickly and precisely. Imagine telling a robot exactly how to make a part you need, from cutting to carving, using computer programs.

That’s what CNC machines do! They work with lots of different materials, making them awesome for creating prototypes or making a small number of parts.

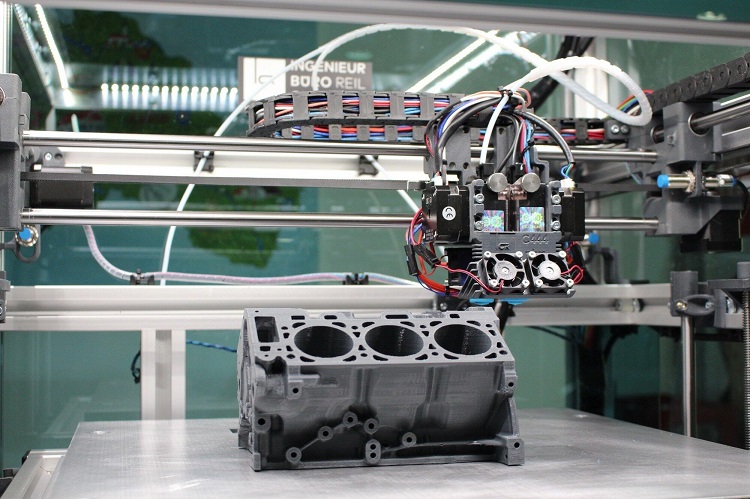

3D Printing/Additive Manufacturing

Additive manufacturing, also known as 3D prototyping, is a game-changer because it lets us create parts directly from digital designs, layer by layer. It’s great for making complex shapes that traditional methods can’t handle. Plus, it’s perfect for custom items or short production runs, allowing for innovation without the high costs.

Laser Cutting and Engraving

Laser cutting and engraving machines use powerful lasers that accurately cut or etch designs into different materials. This method is fast, flexible, and particularly great for creating details or decorations on metal. Since it doesn’t physically touch the material, it avoids warping and results in nice finishes.

Water Jet Cutting

Water jet cutting is like using a super strong water hose that can even have gritty stuff mixed in to help it cut through materials. Unlike methods that use heat to cut, this one keeps things cool, so there’s no worry about the material getting bent out of shape. It’s perfect for cutting materials that can’t handle heat, giving neat and accurate cuts.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is like using tiny lightning bolts to shape materials! It’s perfect for cutting hard materials and making complex shapes that regular cutting tools can’t handle. If you need to make detailed parts that seem almost impossible to do with the usual methods, EDM is the way to go.

Production and Mass Manufacturing Services

Rapid machining isn’t just for making prototypes; it’s also great for big production jobs, like those mass production services in Ohio. This method, especially CNC machining, can handle lots of work, making it easy to go from a single prototype to a lot of products. This means that the fast and creative aspects of rapid machining help in both developing new products and making them in large quantities.

The Future Brightened by Rapid Machining

Rapid machining is the future of manufacturing; it is efficient and new. They can turn ideas into products faster than before.

CNC, 3D printing, and EDM are all being pushed to their limits by product design services. It speeds up product development and makes it easier to customize to meet the needs of a wide range of customers.

Rapid machining is a key part of making industries more flexible. Its growth will make it more useful and solidify its place in modern manufacturing.

Did you like this guide? Great! Please browse our website for more!