Did you know that the global cheese market is expected to exceed $100 billion by 2026? In such a booming industry, dairy businesses are constantly seeking ways to stand out and meet the growing demand for high-quality cheese products. One of the most effective strategies to achieve this goal is through the adoption of cheese processing machines.

These innovative solutions not only streamline production but also ensure consistency, quality, and efficiency, making them indispensable in today’s competitive dairy market. Let’s delve into why your dairy business can’t afford to overlook the benefits of integrating cheese processing machines into your operations.

Table of Contents

Enhanced Production Efficiency

One of the most compelling reasons to invest in cheese processing machines is the significant boost in production efficiency they offer. Traditional cheese-making methods, while artisanal and revered, are time-consuming and labor-intensive. In contrast, automated cheese processing machines can handle various tasks—from curd cutting and whey separation to cheese molding and pressing—with unparalleled speed and precision. This automation reduces the need for manual labor, allowing your workforce to focus on other critical aspects of your business, such as quality control and innovation.

Moreover, cheese processing machines are designed to operate continuously, minimizing downtime and significantly increasing output. For instance, a single automated line can produce thousands of pounds of cheese per day, a figure that would require a much larger workforce and more time to achieve manually. This efficiency not only meets the growing market demand but also positions your business as a reliable supplier capable of handling large orders and scaling operations as needed.

Consistency and Quality in Cheese Production

In the cheese industry, consistency is king. Consumers expect the same taste, texture, and quality every time they purchase your product. Achieving this level of consistency manually can be challenging, as it relies heavily on the skill and experience of the cheesemaker, and is subject to human error. Cheese processing machines eliminate these variables, ensuring that each batch of cheese meets the same high standards.

These machines are equipped with precise controls that regulate temperature, humidity, and other critical factors in the cheese-making process. This precision ensures that every batch of cheese is produced under optimal conditions, leading to a consistently high-quality product. Furthermore, the automation of repetitive tasks reduces the risk of contamination, further enhancing the overall quality of the cheese.

The ability to consistently produce high-quality cheese strengthens your brand’s reputation and fosters customer loyalty. In a market where consumers have endless choices, the assurance of quality can be a significant differentiator for your dairy business, encouraging repeat purchases and word-of-mouth recommendations.

Cost Reduction and Profitability

Investing in cheese processing machines can significantly impact your dairy business’s bottom line. Initially, the cost of purchasing these machines may seem substantial, but the long-term savings and increased profitability they offer cannot be overstated. By automating the cheese production process, you can achieve a higher output with fewer labor costs. This reduction in labor expenses is crucial, especially in industries where margins can be thin.

Automation also leads to a decrease in production errors, waste, and rework, which further reduces costs. For example, precise cutting and portioning machines minimize cheese waste, ensuring that each piece meets exact weight specifications without excess. This precision not only saves on raw materials but also enhances customer satisfaction with consistent product quality.

Moreover, the efficiency and speed of cheese processing machines mean that your business can respond more quickly to large orders or market demands, increasing your competitiveness and ability to capture new opportunities. This responsiveness can lead to higher sales volumes and, consequently, greater profitability.

Meeting Regulatory and Safety Standards

The dairy industry is subject to stringent regulatory and safety standards to ensure that products are safe for consumption. Compliance with these regulations is not just a legal requirement; it’s also critical for maintaining consumer trust and protecting your brand’s reputation. Cheese processing machines play a pivotal role in achieving and maintaining compliance with these standards.

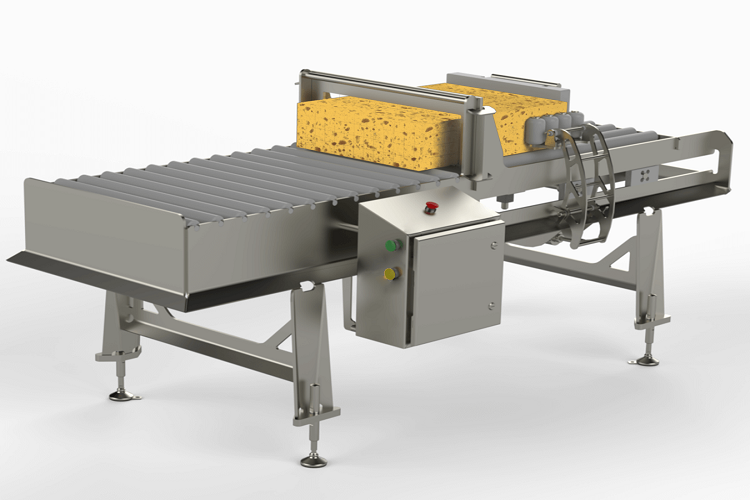

Equipment used in cheese manufacturing today is made with safety and hygienic design in mind. The manufacturing environment is guaranteed to fulfill the highest hygienic standards through the use of automatic cleaning cycles, easy-to-clean surfaces, and stainless steel components, all of which decrease the danger of contamination. Many machines also have capabilities that monitor vital control points, which can be very helpful during audits or inspections as they provide documentation and traceability.

By automating processes, you also minimize human contact with the product, further reducing the risk of contamination. This level of control and cleanliness is challenging to achieve with manual processes and can be a significant advantage in meeting the rigorous demands of food safety regulations.

Conclusion

The integration of cheese processing machines into your dairy business is not just an operational upgrade; it’s a strategic investment in your company’s future. These machines offer unparalleled benefits, from enhancing production efficiency and ensuring product consistency to reducing costs and meeting regulatory standards. In a market that values quality, efficiency, and reliability, the right technology can set your business apart and position it for long-term success.

As the global appetite for cheese continues to grow, now is the time to embrace the advantages that cheese processing machines provide. By doing so, you can meet the demands of today’s consumers and pave the way for a prosperous future in the dairy industry.